Elija la tecnología adecuada para optimizar su proceso de limpieza

Mejore la seguridad alimentaria, el cumplimiento del APPCC, el tiempo de producción, los costes operativos y la seguridad en el lugar de trabajo aplicando tecnología de baja presión con agua impulsada.

La limpieza y la desinfección en la industria de la alimentación y las bebidas son una de las piedras angulares para elaborar un producto que sea seguro para el consumidor.

Por lo tanto, los procesadores están y deben invertir tiempo y dinero para encontrar la solución de limpieza óptima que no sólo mejore la seguridad e higiene de los alimentos, sino que también sea eficiente, sostenible y fácil de usar.

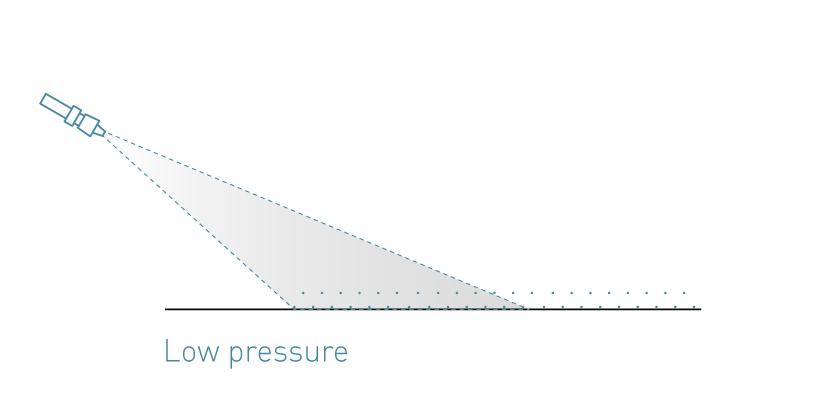

Por tanto, se trata de elegir una solución de limpieza basada en la tecnología adecuada. Mientras que la tecnología de baja presión con agua impulsada ha sido la tecnología de limpieza predominante en Europa en las últimas décadas, sigue siendo relativamente desconocida en Estados Unidos, donde la alta presión es la tecnología más utilizada.

Pero, ¿por qué menos presión es más eficaz que una presión más alta? Siga leyendo para obtener la respuesta.

MENOS ES MÁS

Los estudios demuestran que la baja presión con agua impulsada es la tecnología superior para la limpieza de superficies en la industria alimentaria y de bebidas en comparación con la alta presión. Estos son sólo algunos de los parámetros:

- Mayor impacto del lavado

- Eliminación más eficaz de los residuos

- La menor caída de temperatura

- Reducción del riesgo de contaminación cruzada

- Mejora del entorno de trabajo

La combinación perfecta de la temperatura y el volumen correctos del agua en interacción con los productos químicos significa que nuestras soluciones están optimizadas para la limpieza de las superficies de todo tipo de instalaciones de procesamiento de alimentos y bebidas contaminadas con grasa, bacterias, levadura, microbios, calcificaciones y otros depósitos. De esta manera, todas las superficies no sólo están visualmente limpias, sino también bacteriológicamente limpias.

Aumento del caudal de agua

Las pruebas demuestran claramente que casi el doble de agua llega al objeto/superficie con la limpieza a baja presión en comparación con la alta presión (un 84% más).

Una mayor cantidad de agua sobre el objeto/superficie reduce significativamente el tiempo de limpieza y acelera la eliminación de los residuos. El efecto del aumento del caudal reduce el consumo total de agua.

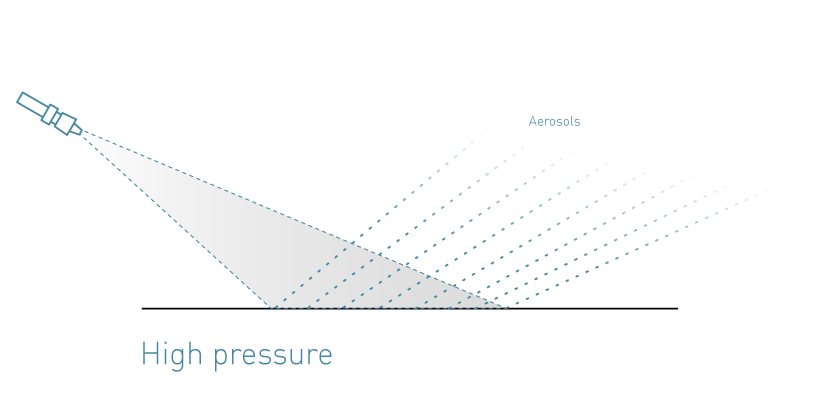

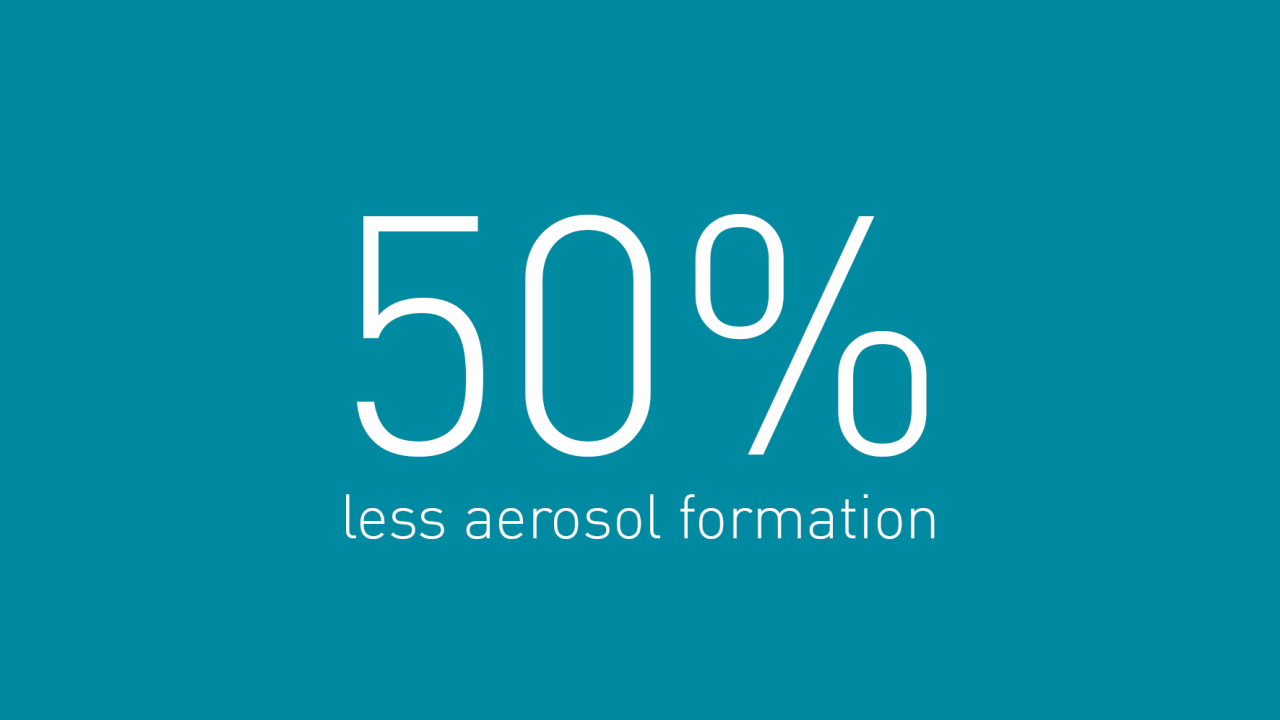

Reducción de la formación de aerosoles

Se ha prestado atención a los aerosoles en relación con la limpieza, ya que forman pequeñas gotas que se esparcen en el aire y se inhalan fácilmente, con el riesgo de causar problemas respiratorios. Los aerosoles también pueden transferir partículas contaminadas a superficies ya limpias.

Con la limpieza a baja presión, las gotas que se forman son más grandes y llegan más rápidamente a la superficie, lo que reduce el riesgo de dispersión en el aire. Las pruebas demuestran que la reducción es de al menos un 50%.

La aplicación de la tecnología de baja presión con agua impulsada para la limpieza en sus instalaciones de procesamiento mejora significativamente una serie de parámetros clave

Una buena higiene en la producción y una limpieza correcta son esenciales cuando se quiere producir productos de calidad con un alto nivel de seguridad alimentaria y una vida útil óptima.

La optimización del proceso de limpieza mediante el uso de la tecnología adecuada no sólo tendrá un impacto positivo en la calidad de sus productos, sino que también mejorará el entorno de trabajo del personal de limpieza y reducirá el tiempo de limpieza y el consumo de agua.

Descargue nuestra guía tecnológica a continuación y obtenga una visión más detallada de las diferencias entre la limpieza a baja presión y a alta presión.

Descargue nuestra guía tecnológica a continuación y obtenga una visión más detallada de las diferencias entre la limpieza a baja presión y a alta presión.